Energy saving

- Home

- Products

- Pocket filters

- Energy saving

| Filter class ISO 16890 | From ePM1 60% to ePM1 85% |

| EN 779:2012 class (previous standard) | From F7 to F9 |

| Material | Progressive synthetic |

| Frame | Galvanized steel |

| Permanent operating temperature | < 70°C |

| Relative humidity | 100% |

| Recommended final pressure drop |

The smaller value parameter must be selected: ePM10 / ePM2.5 / ePM1:

|

| Max. final pressure drop | 450 Pa |

Pocket filters – the most widely used air filters. The modern metal outer frame is connected without the use of rivets or screws. This ensures a tight seal between the unit‘s construction and the filter, protecting the gaskets inside the unit.

By choosing our pocket filters, you are investing in an innovative, efficient, and long-lasting solution that will improve your air quality and help reduce the operational costs of your ventilation system.

FILTER MEDIA

Synthetic media: We offer a wide selection of synthetic filter media. These are usually made from polyester or polypropylene fibers. These materials are highly resistant to moisture, chemicals, and mechanical damage. Synthetic materials also ensure high filtration efficiency, effectively collecting dusts, allergens, microorganisms, and other harmful particles.

Fiberglass media: High-quality fiberglass microfiber material, formed on a polyester base and made from special borosilicate glass. The production of this material uses extremely high temperatures. The fiberglass media is sensitive to damage.

INNOVATIVE FILTRATION SOLUTIONS

Modern sewing technologies in the production of pocket filters allow for the creation of highly efficient filters, maximizing the use of the filtration surface. By using advanced engineering techniques and specialized equipment, we manufacture uniquely designed filter pockets.

OUR INNOVATIONS

Consistent airflow: The carefully calculated arrangement and depth of the pockets ensure an even distribution of airflow across the filter surface. This minimizes pressure drop and increases filtration efficiency.

Modern pocket technology: A special pocket design ensures the pockets remain separate, preventing them from touching each other or the internal surfaces of the air handling unit. This design maximizes the usable filtration area, enhances the collection of dust and other particles, and extends the filter‘s service life.

Sealed stitches: A special manufacturing process ensures the stitched lines of the pocket filters hermetically sealed. This ensures the filter‘s integrity and prevents pollutants from penetrating through the seams, thus protecting the components of the ventilation unit from contamination.

Durability: High-quality materials and a robust design ensure the filter‘s durability, even under high airflow conditions.

Lower energy costs: Low pressure drop and modern pocket filter construction reduce the energy consumption required for the operation of the ventilation system.

How to correctly measure pocket filters?

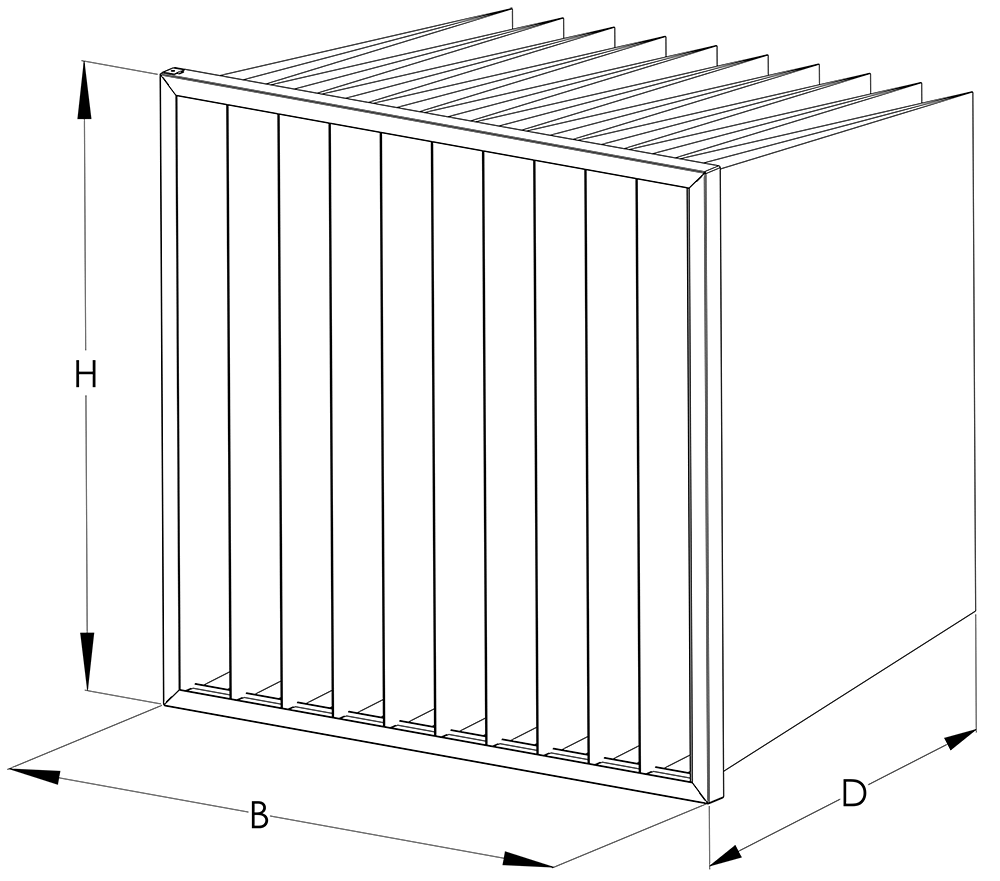

- Place the filter in the same position as shown in the picture.

- Record the measurements in the following order (do not mix them up): B (width) × H (height) × D (depth) mm.

-

Indicate the required number of pockets.

We also manufacture filters with custom dimensions.

Air filter characteristics

|

Filter class |

EN779:2012 |

Dimensions |

Number of pockets |

Air flow (m3/h) |

Pressure drop (Pa) |

Energy class |

|

ePM1 85% |

F9 |

592x592x635 |

12 |

3400 |

114 |

A |

|

10 |

108 |

S |

||||

|

592x592x535 |

12 |

136 |

C |

|||

|

10 |

126 |

C |

||||

|

ePM1 65% |

F7 |

592X502X635 |

10 |

82 |

B |

|

|

8 |

73 |

C |

||||

|

592x592x535 |

10 |

95 |

C |

|||

|

8 |

84 |

D |

||||

|

ePM1 60% |

592X502X635 |

10 |

76 |

A |

||

|

8 |

73 |

B |

||||

|

592x592x535 |

10 |

83 |

B |

|||

|

8 |

80 |

C |