Minipleat Cardboard

- Home

- Products

- Compact filters

- Minipleat Cardboard

| Filter class ISO 16890 | From Coarse 80% to ePM1 80% |

| EN 779:2012 class (previous standard) | From G4 to F9 |

| Material | Progressive synthetic or fiberglass |

| Frame | Moisture resistant cardboard |

| Permanent operating temperature | < 70°C |

| Relative humidity | 100% |

| Recommended final pressure drop |

A lower parameter must be selected: ePM10 / ePM2.5 / ePM1:

Coarse:

|

| Max. final pressure drop | 200 Pa |

Compact filters are widely used in both residential and industrial ventilation systems, where the priority is the compact design of the air handling unit. By using pleated media technology, we achieve a large filtration area and rigidity in compact filters.

ADVANTAGES:

- Large filtration area

- Durable compact design

- Easy replacement

FILTER MEDIA

Water-resistant progressive synthetic filter media are usually made from polyester or polypropylene fibers. These materials are water-resistant, making them suitable for use in humid environments.

INNOVATIVE FILTRATION SOLUTIONS

The modern manufacturing process and innovative materials make it possible to achieve low pressure drops, extended service life, and ensure mechanical resistance. Special adhesives are used to maintain separation between the filter pleats. These adhesives help maintain a consistent gap between the pleats, preventing them from touching during operation. This way, the pressure drop in the ventilation system is not increased.

INNOVATIVE MATERIALS

Moisture resistance and durability: helps maintain the filter‘s structure and performance in high humidity conditions, extending the filter‘s service life.

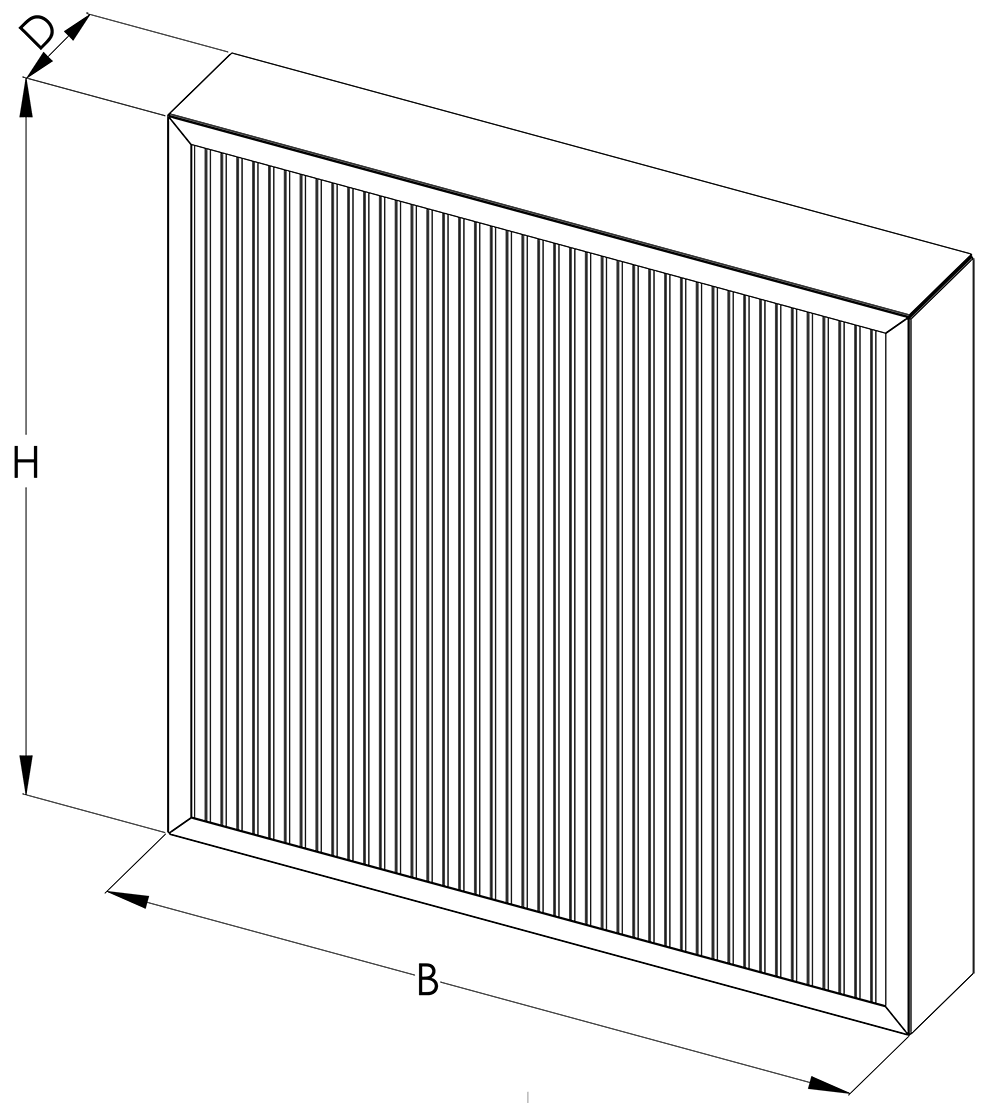

How to correctly measure compact filters?

- Place the filter in the same position as shown in the picture.

- Record the measurements in the following order (do not mix them up): B (width) × H (height) × C (depth) mm.

We also manufacture filters with custom dimensions.