Compact

| Filter class ISO 16890 | Coarse 80% and ePM1 60% |

| EN 779:2012 class (previous standard) | G4 and F7 |

| Material | Activated carbon with high-quality synthetic material |

| Frame | Moisture-proof cardboard, high-quality plastic, fiberplast, foam |

| Permanent operating temperature | < 70 °C |

| Relative humidity | < 100 % |

| Recommended final pressure drop |

The smaller value must be selected: Coarse:

|

Activated carbon filters are designed to capture various substances dissolved in the air from the supplied or exhausted air. Carbon filters effectively trap tobacco smoke, food odors, gasoline fumes, phenol vapors, and other substances emitted in household, public, and industrial environments.

ADVANTAGES:

- High adsorption of harmful gases and odors

- The effectiveness of mechanical filtration does not decrease throughout the filter’s service life

- High filter quality with low air flow resistance

Filter media

The structure includes activated carbon granules. The structure of these granules consists of numerous open pores. This significantly increases the activated carbon’s ability to absorb chemicals, which bond with the open carbon pores.

Activated carbon filters are an advanced air purification technology used to remove various pollutants, chemicals, and odors from the air. Activated carbon filters are highly effective due to their unique structure: the carbon is specially processed and activated to create an extremely porous material that absorbs various pollutant particles.

HOW DO ACTIVATED CARBON FILTERS WORK?

Adsorption: The main operating principle of activated carbon filters is adsorption. Due to their highly porous structure, the carbon creates a vast surface area that attracts and holds the molecules of chemical compounds.

Efficiency: These filters are particularly effective against volatile organic compounds (VOCs) as well as various odors.

Modern structure and increased capacity: Modern activated carbon filters are produced with pores of various sizes.

MODERN TECHNOLOGIES AND ADVANTAGES

Activated carbon filters, due to their efficiency and reliability, are an essential part of modern ventilation systems, ensuring cleaner air both in households and in industry.

How to correctly measure activated carbon filters?

How to correctly measure activated carbon filters?

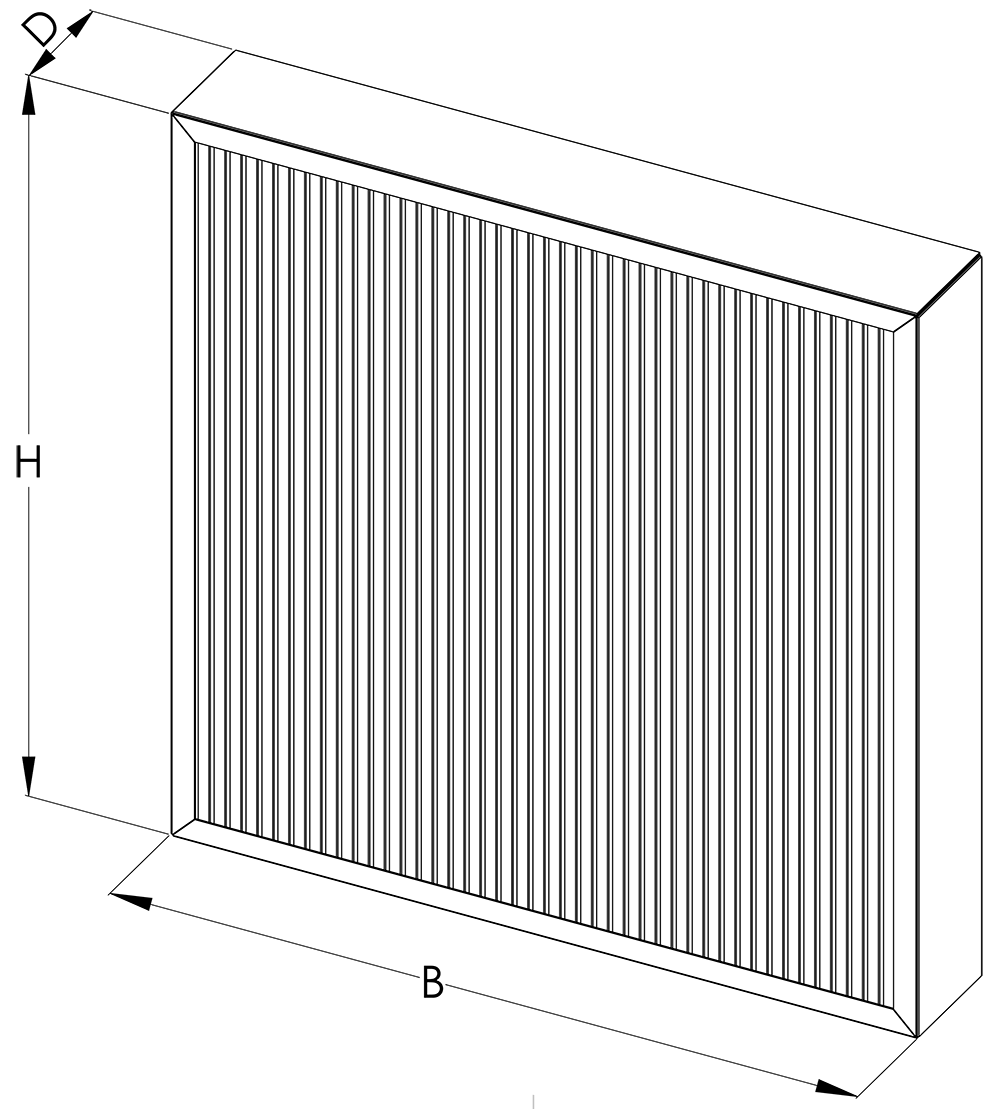

- Place the filter in the same position as shown in the picture.

- Record the measurements in the following order (do not mix them up): B (width) × H (height) × D (depth) mm.

We also manufacture filters with custom dimensions.

Air filter characteristics

|

Filter class ISO16890 |

EN779 :2012 |

Dimensions |

Air flow (m3/h) |

Pressure drop (Pa) |

|

ePM1 60% |

F7 |

592×592×48 |

3400 |

180 |

|

592×592×96 |

1700 |

|||

|

Coarse 80% |

G4 |

592×592×48 |

2800 |

55 |

|

592×592×96 |

1700 |