HEPA, EPA, ULPA

- Home

- Products

- Absolute filters

- HEPA, EPA, ULPA

| Material | Glass fiber |

| Frame | Plastic, aluminum, MDF, galvanized steel |

| Permanent operating temperature | < 70°C |

| Relative humidity | 100% |

| Max. final pressure drop | 600 Pa |

HEPA, EPA, and ULPA filters are absolute filtration filters capable of capturing even the smallest airborne particles – bacteria, dust, and viruses. These filters are used in environments with extremely high cleanliness requirements, such as medical facilities, pharmaceutical manufacturing plants, high-tech industries, etc.

FILTER MEDIA

High-quality fiberglass: Fiberglass filters are distinguished by exceptionally high filtration efficiency. Due to the unique structure and texture of the material, they effectively capture various very small and harmful particles – bacteria, allergens, mold spores, and chemicals. This ensures compliance with cleanroom standards. Fiberglass filters maintain their filtration properties for an exceptionally long time.

Before HEPA filters, it is recommended to use ePM1 class filters.

HEPA (High Efficiency Particulate Air) filters are one of the most advanced air filtration technologies. HEPA filter technology is continuously improved to ensure the highest efficiency, durability and suitability for various conditions.

HOW DO HEPA FILTERS WORK?

HEPA filters effectively remove almost all harmful particles from the air. Particles are collected in the filter fibers through three main processes: interception, diffusion, and inertia. Thanks to these processes, HEPA filters effectively capture both large and small particles, including the smallest ones.

ADVANTAGES

- High filtration efficiency.

- Each filter is individually tested according to EN 1822 and ISO 29463.

- Different frame types are available.

- The HEPA filter is selected individually based on airflow and other parameters.

| Standard |

1822 EN |

ISO 29463 |

Integral value |

Integral value |

Local value |

Local value |

| EPA |

E10 |

– |

≥85 |

≤15 |

– |

– |

|

E11 |

ISO 15 E |

≥95 |

≤5 |

– |

– |

|

|

– |

ISO 20 E |

≥99 |

≤1 |

– |

– |

|

| E12 |

ISO 25 E |

≥99,5 |

≤0,5 |

– |

– |

|

|

– |

ISO 30 E |

≥99,90 |

≤0,1 |

– |

– |

|

| HEPA |

H13 |

ISO 35 H |

≥99,95 |

≤0,05 |

≥,99,75 |

≤0,25 |

|

– |

ISO 40 H |

≥99,99 |

≤0,01 |

≥99,95 |

≤0,05 |

|

| H14 |

ISO 45 H |

≥99,995 |

≤0,005 |

≥99,975 |

≤0,025 |

|

|

ULPA |

– |

ISO 50 U |

≥99,999 |

≤0,001 |

≥99,997,5 |

≤0,005 |

| U15 |

ISO 55 U |

≥99,999,5 |

≤0.000,5 |

≥99,997,5 |

≤0,002,5 |

|

|

– |

ISO 60 U |

≥99,999,9 |

≤0,000,1 |

≥99,999,5 |

≤0,000,5 |

|

| U16 |

ISO 65 U |

≥99,999,95 |

≤0,000,05 |

≥99,999,75 |

≤0000,25 |

|

|

– |

ISO 70 U |

≥99,999,99 |

≤0,000,01 |

≥99,999,9 |

≤0,000,1 |

|

| U17 |

ISO 75 U |

≥99,999,995 |

≤0,000,005 |

≥ 99 999 9 |

≤0,000,1 |

How to correctly measure HEPA filters?

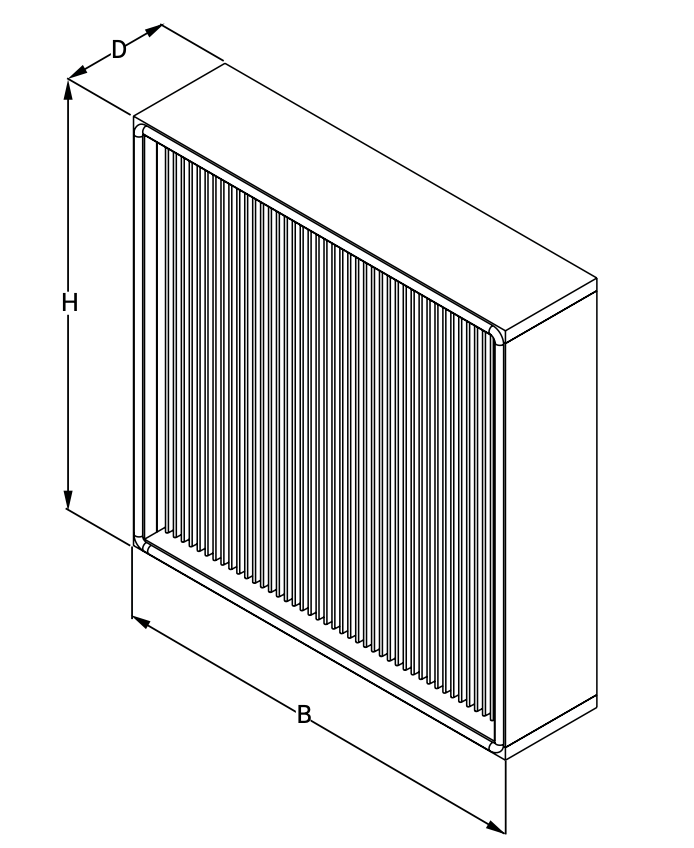

- Place the filter in the same position as shown in the picture.

- Record the measurements in the following order (do not mix them up): B (width) × H (height) × D (depth) mm.

We also manufacture filters with custom dimensions.